Impulsamos el desarrollo sostenible de nuestras comunidades

Las empresas del Grupo Techint iniciamos un proyecto global y de largo plazo, basado en la educación como pilar fundamental del progreso individual y social.

59.299

personas alcanzadas por los programas educativospersonas alcanzadas por año

20

paísespaíses

49,7

millones de dólares invertidos en programas educativos por añomillones de dólares invertidos en programas educativos por año

Empresas del Grupo Techint que lideran estos programas educativos

Estas compañías están involucradas en el diseño, la implementación, la mejora continua y el soporte financiero de cada uno de los programas.

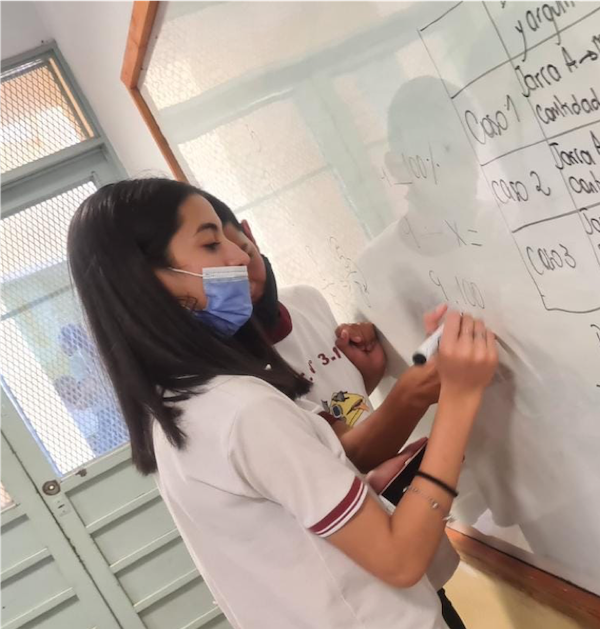

Programas educativos Roberto Rocca

Pasión por la educación

En 1945, Roberto Rocca se unió a su padre Agostino en la fundación de Techint. Desde los inicios, la visión que acompañó el proyecto industrial -que con los años se expandiría globalmente- era crecer de la mano de las comunidades vecinas, con base en la educación como herramienta clave para el progreso individual y social.

Roberto Rocca tuvo un rol fundamental, respaldando una gran variedad de iniciativas dedicadas al aprendizaje a todos los niveles, así como a la investigación. Bajo el impulso de su nombre, hoy la propuesta educativa de las empresas del Grupo Techint conserva una línea rectora y genera sinergias que la potencian.

Escuelas Técnicas Roberto Rocca, Gen Técnico Roberto Rocca, Extra Clase Roberto Rocca y Becas Roberto Rocca. Cada uno de estos programas es parte de un proyecto global, que tiene como objetivo fomentar un vínculo estrecho con las comunidades en las que operamos. Esto nos permite crecer y aprender juntos, desarrollando un fuerte sentido de pertenencia, y compartiendo un compromiso a largo plazo.

La voz de los protagonistas

Accede al Informe Anual de Relaciones con la Comunidad 2022

Alianzas estratégicas